Plastic products are a common material in our daily life. They can not only make all kinds of living utensils, but also make all kinds of industrial products. The use value of plastics is so great. According to the general statistics, up to now, there are about 100 kinds of plastic materials known in the world, and these kinds of plastics are widely used

PP material

PP material (polypropylene) is a kind of very safe and light plastic material with good heat resistance, unique luster on the surface and easy to be processed to present bright colors; due to its high bending strength, some kinds of materials will be preferentially used in the production of some integrated containers (such as those with box cover and box body). PP plastic box is also a transparent packaging box made of this kind of plastic, which will be commonly used in the packaging of some infant products.

PVC tube

PVC material (PVC), the biggest characteristic of PVC material is that it can add different additives to make various kinds of soft and hard articles with different texture and different uses, and its plasticity is very strong. PVC material has low cost, good transparency and good flexibility, which is suitable for making all kinds of Blister products and PVC packaging boxes.

PET material

PET material (polyethylene terephthalate) pet can also be used as fiber. The biggest feature of pet is that it has a complete recycling system. Because of its environmental protection and safety, this highly efficient material is widely used in the plastic box and blister packaging industry.

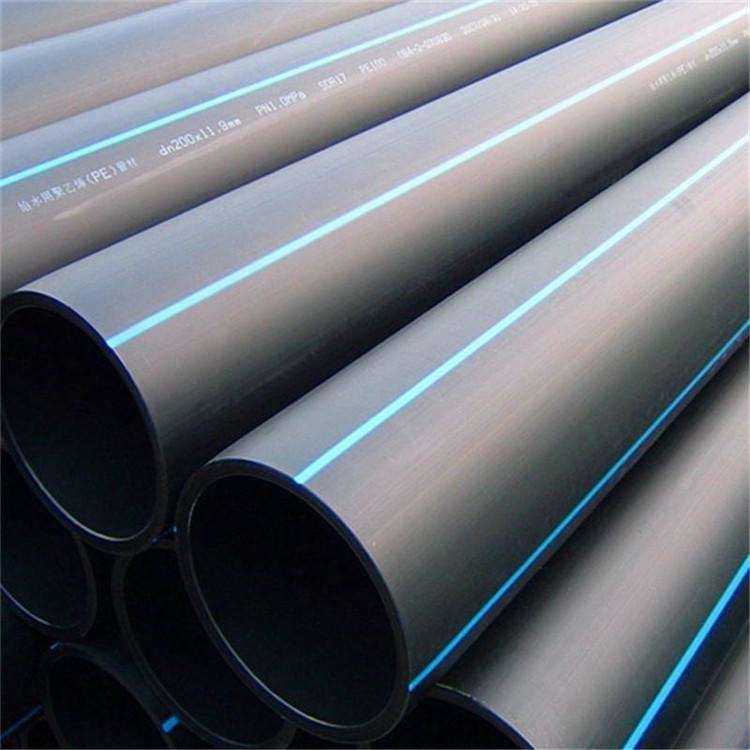

PE material

In addition to the above three materials, such as: Polyethylene (PE), is a kind of raw material which is often used to process and produce fresh-keeping film and plastic bags. Because of its low price, PE is easy to form, and it is also a commonly used material for the production of plastic buckets. PE is not heat resistant, but can withstand low temperature of - 20 ℃.

PS material

Polystyrene (PS), the former CD box is produced and processed with PS, which is also a common material for plastic models. PS is easy to dye, but PS is not heat-resistant and easy to crack, but it is easier to process anti-static products, which are often used in the electronic industry. Such as PS anti-static plastic tray is one of the products.

ABS material

ABS resin, higher than PS strength, in the molding liquidity is very good, is a very common material used in the injection molding industry.

PC material

PC (polycarbonate), with good strength, is the preferred material for making products with high transparency and high strength. It is often used to make CD discs and has good light resistance.

PA material

PA material (nylon), which is a kind of plastic material used as fiber. PA has good tensile, compression and bending properties. PA is often used to make various parts.

Therefore, these materials are commonly used in plastics after heating.

- What are the specific classifications of metals?

- 2020-06-09

- Non ferrous metalsNon ferrous metals: aluminum, 2113 magnesium, potassium, sodium, calcium, strontiu...

- Plastic pipe classification: 6 kinds of common pipes are made of plastic!

- 2020-06-09

- It is a kind of high cost-effective plastic material and is popular among consumers. So, starting fr...

- Types and differences of plastics

- 2020-06-09

- Plastic products are a common material in our daily life. They can not only make all kinds of living...